Researching before purchasing is essential when selecting the best materials to use in your building or construction project. Due to its low cost and high durability, aluminum extrusions are a standard building material.

Aluminum is also highly sought after for metallic detailing in glass installation, as you can use the extrusions to create different shapes in complex construction projects. Read on for aluminum extrusion considerations if you're in the midst of a building project or about to begin one.

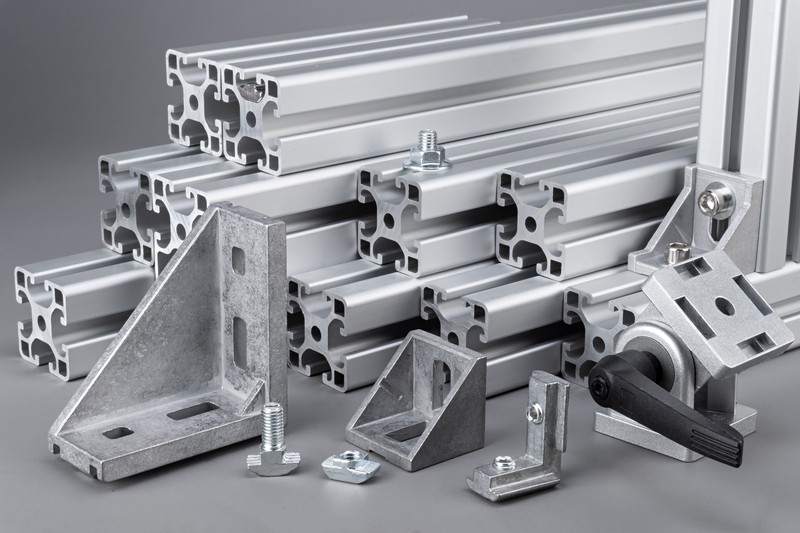

Aluminum extrusions are manufactured by extruding or pressing a billet of aluminum through a die to produce the desired shape. The impact will depend on the size of the piping tip you use. To force the aluminum alloy through the die and into the desired shape, you must use a hydraulic press during the extrusion process.

The extrusion process allows manufacturers to make different lengths, widths, depths, thicknesses, and shapes. You can use both continuous and semi-continuous processes to achieve this goal. Although hot extrusion is more common, cold extrusion works better because it results in a harder material and a smoother finish.

Aluminum's wide range of beneficial physical properties includes resistance to corrosion, sleek appearance, and a high strength-to-weight ratio. Choosing the suitable aluminum alloy for a product's intended use allows designers to highly various characteristics.

Aluminum extrusion profiles have many potential applications in construction due to the mentioned physical properties. Railings and bleaching agents are two of the many uses for aluminum extrusion profiles. In addition to exterior design, you can use aluminum extrusions on staircases, elevator lobbies, and hallways.

You must note that aluminum isn't strong enough to be used as the main framework of a building, but it can be used to accentuate and support the structure from the inside. Extruded aluminum is incorporated into a building's design at nearly every stage, from the framework to the mechanical and plumbing systems. When choosing an alloy, the following are some variables to think about ;

One of aluminum's best qualities for use in building is its remarkable structural strength. Aluminum's strength is close to steel while it weighs lighter. Avoid choosing a metal just to meet a weight requirement; aluminum extrusions will allow you to build a more robust structure without the added weight of steel.

Aluminum extrusions are resistant to rust and other forms of corrosion, which means it never rusts because an oxide film forms naturally on its surface that serves as a protective layer. Also, you can anodize, powder coat, or paint with PVDF paints, all of which add a layer of corrosion resistance and aesthetic appeal to the surface.

Aluminum's recyclability and durability in construction are gaining importance as more homeowners opt for deconstruction over demolition. Deconstruction is preferable to landfill disposal because recyclables can be salvaged and their scrap value maintained.

Putting the framework together requires using standard hand tools and saves time. This eliminates the need for welding because the connections are sturdy but temporary.

To create aluminum extrusions, manufacturers design a cross-section and push the material through a die, which allows the material to be shaped and sized to fit any project, regardless of its dimensions or specifications. Machines, products, and structural frames rely on them because they allow the fabrication of almost any size or shape.

The most cost-effective way to acquire aluminum extrusion for major constructions is to purchase bulks of material in whatever lengths are available and then have it cut to the desired dimensions. If you do it yourself, use a sharp, square blade to ensure the extrusions line up properly when you join them.

If you purchase brand-new extrusions, you can usually have them fabricated precisely to the dimensions you specify. If you're cutting the long pieces, this could help you save money on shipping. You can also order the material in various colors or metal alloys in addition to the cuts.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238