Aluminum extrusion describes the method of pushing an aluminum alloy through a predetermined cross-sectional profile.

In this procedure, the physical properties of aluminum are exploited. The malleability or flexibility allows for simple manipulation. The final product is solid and stable despite being made of aluminum, which is just a third as tough as steel.

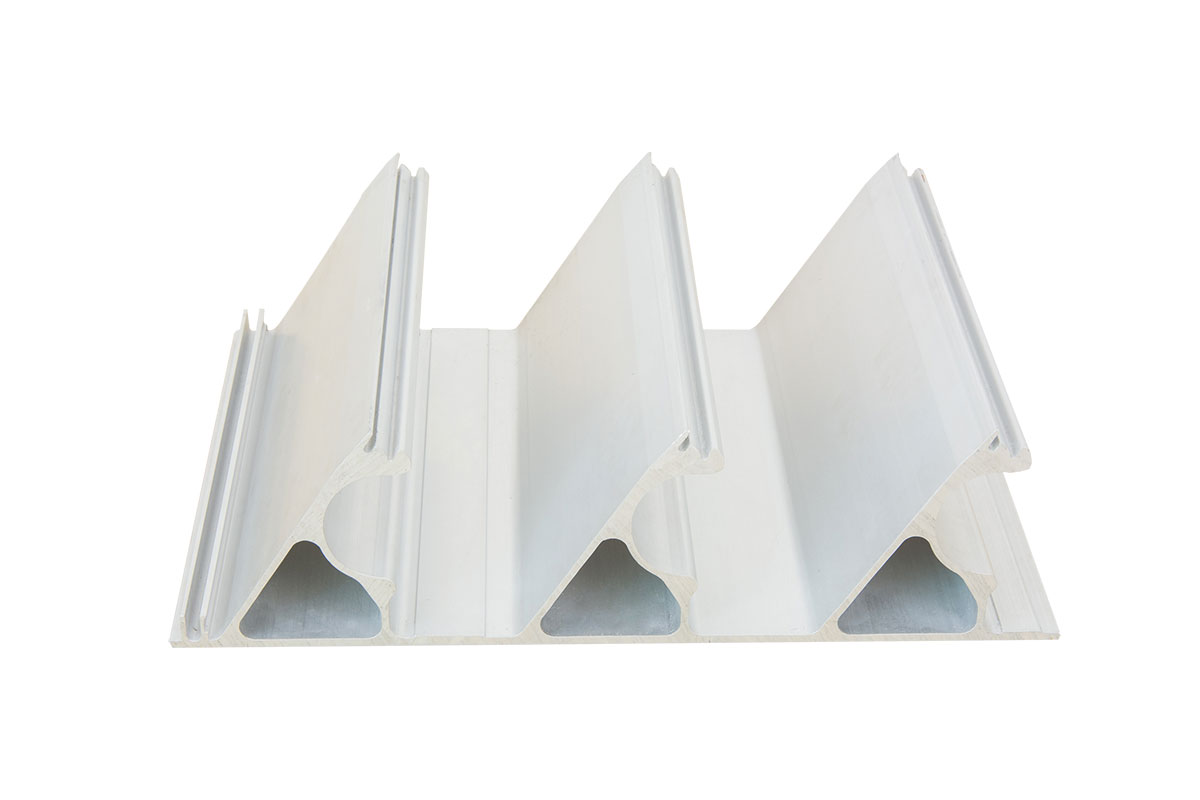

There is a wide selection of aluminum framing profiles, each with a specific use. Profiles, or cross sections, can be found in a wide range of thicknesses, each of which contributes significantly to a building's aesthetics or practicality.

Aluminum's favorable physical qualities make it a popular choice for use in profile production, much to the delight of manufacturers. Aluminum has many desirable properties, including being inexpensive, easily worked, having a wide range of applications, and being an excellent thermal conductor.

Aluminum beams without cross-sections are meant by "hollow beam profiles." These play a crucial role in modular building and are employed in various ways. There are many different types of hollow beams, and they are further classified based on their shapes. These are available as triangular, square, or rectangular beams. Structures such as buildings and bridges often make use of hollow beams for their support systems.

These framing profiles are a subset of aluminum hollow beams. Square beams serve a similar purpose as hollow ones but with the added benefit of offering more permanent and stable support. Load bearings for walls and pillars often feature square profiles. The production method determines whether or not the resulting square profile is seamless. In order to create square profiles, you must repeatedly flatten an aluminum sheet and join the corners so that the resulting shape is square.

Small- and large-scale uses alike benefit from aluminum profiles. Extruded aluminum systems are frequently utilized in window framing. Aluminum is an excellent choice for window framing because it is lightweight, can be manipulated easily, and is corrosion-resistant.

SD aluminum profiles are the most popular option for sliding windows. Since windows are constantly being subjected to the elements (rain, sun, storm, humidity, dust, etc.), they must be constructed from a durable material.

SD aluminum profiles are superior to other options for window framing due to their resistance qualities and sliding flexibility.

RCW profiles are typically installed on mullions and curtain walls in tall buildings. In contrast to their structurally-related counterparts, RCW profiles serve only as a weather barrier, keeping out dust and precipitation.

Curtain walls typically have an aluminum frame and come in various sizes to suit any need. These profiles address the crucial issue of preventing unwelcome materials from accessing the premises. RCW profiles are outfitted with additional materials to ensure that leaks don't happen.

Door sections, also known as ED sections, are utilized in industrial-strength glass door installations. Push doors rely on them as a crucial component of the mechanism.

Many commercial buildings have glass doors but no mechanisms. The timeless style successfully merges form and function. The aluminum door portions are very helpful in keeping the glass in place and avoiding any accidents.

Louvers are angled slats spaced uniformly apart on a shutter, door, or screen to let light in. Louvers let in air and light from outside the building. They provide another practical use by preventing dust and dirt from entering the building.

The architectural style of a building determines the design options for aluminum louvers. Using aluminum means that the interior may be kept cool by natural ventilation and protected against water intrusion.

T-shaped aluminum extruded parts provide multidirectional support. T-section products feature elements like horizontal flanges and vertical webs.

Thanks to its design, this profile works well in 90-degree corners and truss systems. Modifications, such as adding square or hollow beam profiles, are simple to do with this system. Fittings are also affixed to the T-section, increasing the level of support, which contributes to the T-overall section's durability.

Sustainable design, aesthetics, practicality, and structural support are all factors in today's wide variety of profile forms. Manufacturers of aluminum profile extrusions have responded to the demand for more specialized products by including modifications to their profiles for use in situations like heavy-duty doors, sliding doors, and window framing.

Even though aluminum profile extrusions were initially employed in the building industry for their structural benefits, they have since been shown to be of great value in weatherproofing.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238