Aluminum is one of the most versatile raw materials on the planet. As a result, it is typically the preferred choice when it comes to numerous applications across various industries. Another sector that it is also well suited for is aluminum extrusion. However, both aluminum alloys of 6061 and 6063 are very similar. This means that they are often used for the same applications, thereby making it difficult for some manufacturers to choose between the two.

Regardless, knowing or understanding the specifications mentioned is not the same as seeing how the alloys will actually respond in different settings. This is why manufacturers have to test each one to ensure that it performs as expected. Failure to do so can sometimes lead to structural integrity issues.

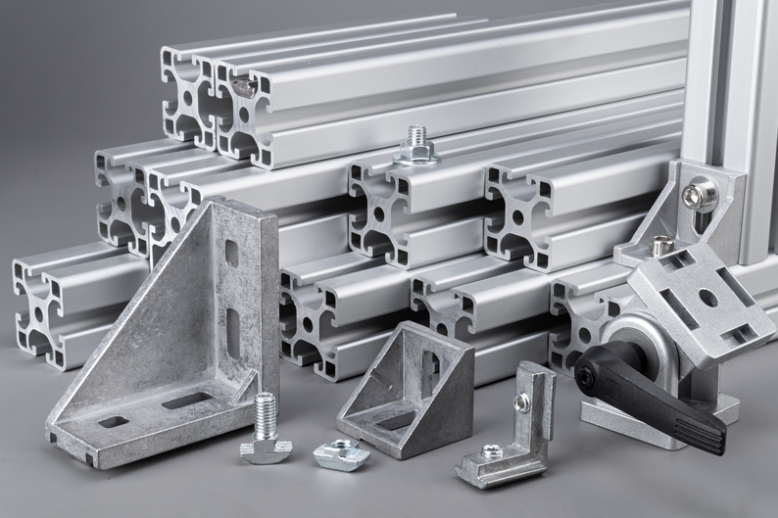

Extrusion refers to transforming materials like metal, rubber, or plastic into various kinds of items and shapes intended for different uses in various sectors. Because of its physical properties, aluminum is an ideal raw material for extrusion. The alloy has both formability and malleability, which means it can easily be machined and cast depending on one’s needs and requirements. It is also around a 1/3 the density of steel.

This means that the extrusions are both stable and robust whilst being cost-effective compared to other materials. This is also another reason why aluminum has become the most common metal for extrusion.

There is no argument that aluminum is very popular because of its diverse range of alloys. Nonetheless, not all of them are suitable for extrusion. In most cases, three classes of these alloys are used during extrusion: they are the 1000, 6000, and 7000 series.

When it comes to strength, manufacturers and users typically agree that the 6000 series cannot compare to the 2000 and 7000 series. However, it still has various beneficial features, such as good welding capabilities, corrosion resistance, and easy forming.

The 6000 series is represented in several categories, which include the 6061 and 6063. The former is used in various structures like cranes and towers.

They can also be found in different regions across Europe and the United States since they have ideal corrosion-resistant features and barely need any anti-rust treatment.

Before we go further into the differences between the 6063 T5 and T6, consumers need to understand the following terms:

This refers to the process of eliminating the internal stress present in metals.

This refers to when the metal is heated to a particular temperature and rapidly cooled to match the required hardness. This can result in in varying strengths of 2. 6, and 7 series aluminum sheets. Further quenching treatments can also occur to increase them.

When talking about T5, we are referring to the temperature that aluminum alloys are rapidly lowered to through air cooling once extrusion from the extruder is complete. This is also done to adhere to the required hardness levels, i.e., Wechsler 8-12 hardness.

Conversely, T6 refers to the instant cooling of aluminum alloys using water after extrusion from the extruder has taken place. This is done to allow the aluminum sheet to achieve higher levels of hardness.

With an air-cooling system, the process can take a relatively long time of around 2 to 3 days, which is also referred to as natural aging. Conversely, water cooling, also referred to as artificial aging, is a much faster process. You are likely wondering - what sets the T5 and T6 states apart? Well, that’s their strength levels. T6 is often much stronger than T5 and is better in many other ways.

By this point, pricing must have come to mind; well, T6 aluminum is often costlier than T5 aluminum. The price variance typically results from the different production requirements.

T5 aluminum can be applied in everyday settings like solar frames. However, if you require specialized aluminum profiles with high strength levels, you should use T6 aluminum. It also has better-performing features for various settings.

Since both the T5 and T6 alloys are in the same series category and, therefore, have some similar chemical makeups, it can still be tricky to differentiate the two from one another using a materials-based standpoint. In most cases, it would be easier to determine the differences by closely examining what makes these practical and valuable in their respective applications, which is mainly their differing strengths. Also, it would be best if you kept in mind that these strengths can vary depending on the heat treatment used.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238