Aluminum framing is the absolute star of modern manufacturing due to its elegant appearance and simple function. Aluminum framing provides numerous benefits to any sector because it is versatile, practical, and easy to use.

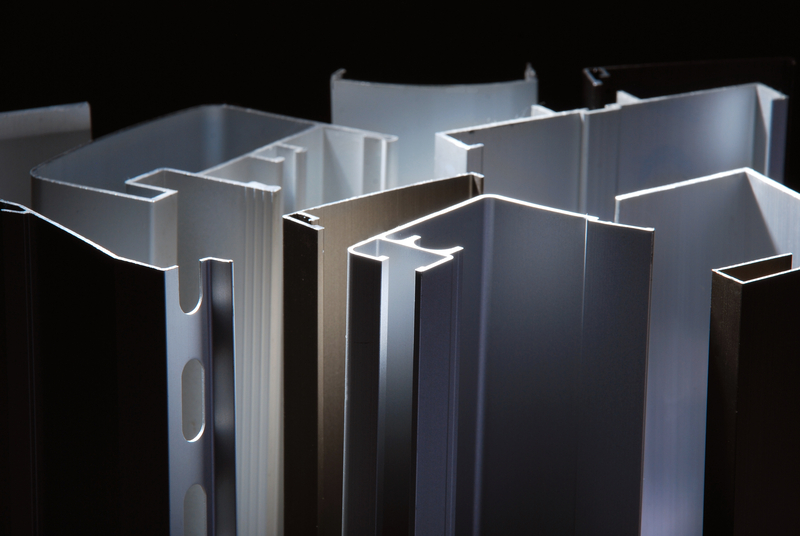

Aluminum frames are made up of hollow profiles known as aluminum extrusions, often used as structural elements in a variety of designs. A thermal break, often made of plastic or rubber, reinforces the hollow interior.

Aluminum frames have numerous advantages that make them a good choice for most applications, particularly commercial ones.

Aluminum framing promotes safer workplaces. Physical enclosures, barriers, and guards built of aluminum framing safeguard equipment and prevent unexpected workplace disasters. These can be easily fabricated from standard fittings for speedy installation.

Aluminum framing boasts a higher strength-to-weight ratio than framing made of steel and other materials. It’s also lighter and, therefore, easier to manipulate during setup. Furthermore, the structure itself (window, door, etc.) closes and opens smoothly.

Furthermore, aluminum is rust-proof, so it does not require paint or additional rust-prevention treatment. It naturally generates an aluminum oxide surface layer, which acts as a physical barrier against corrosion.

Selecting aluminum framing with a clean finish and a visually pleasing appearance saves time and money by avoiding the need for further painting or finishing to finalize the project.

Aluminum frames provide better insulating value than steel and wood frames because they can handle thicker panes without increasing weight or frame depth. The home will be able to retain more heat, leading to a more consistent temperature and reduced energy expenditures.

Structures for nearly any weight or application can be easily erected without requiring specific skills or product expertise, thanks to the availability of numerous bolt-together connectors and hundreds of distinct strut profiles.

Thus, using aluminum framing instead of traditional welded steel to construct structures saves the company money and time on both labor and materials.

Aluminum frames are reusable, making it easy and economical to alter structures as the application demands. It's easy to modify and tough enough to sustain hundreds of adjustments, allowing users to achieve desired structural designs.

Aluminum framing encourages ideas outside the traditional manufacturing box. Aluminum framing's adaptability makes it useful in a wide variety of industries and applications. Even the most stringent applications, such as medical equipment manufacturing, are possible with the correct aluminum framing profile.

Most aluminum framing solutions require the fabrication of aluminum framing parts cut into various profiles. Choosing an aluminum framing solution requires a thorough examination of product specs and supplier potential. A range of parameters, such as weight, physical dimensions, treatment, tolerance, and modulus of elasticity, are used to specify aluminum framing solutions and their constituent elements.

Aluminum framing is a great choice for any construction project looking to save money and time on labor and parts. Indeed, with the proper aluminum framing profile, setting up structures for the specific needs of a project is easy. It’s used in interior design, ceiling and wall structures, assembly lines, retail displays, houses, and workstation projects. Allow your imagination to run wild with JMA aluminum framing—a framing profile that includes everything you need to construct pretty much anything.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238