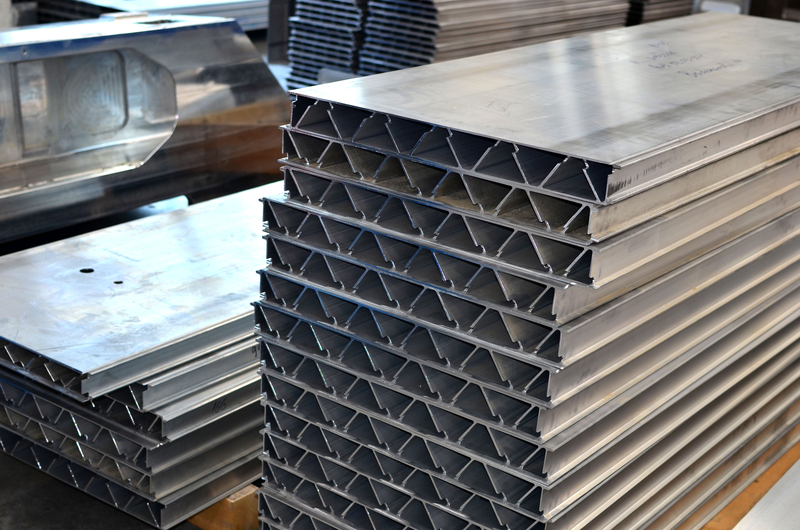

When it comes to aluminum profiles, their importance can never be overemphasized as they are used in so many fields, household and commercial. Are you looking into industrial aluminum profiles? Do you need to select the right ones for your business? You have come to the right platform. Continue reading for tips on how to choose profiles that match your needs.

You will find aluminum profiles in construction, automotive, aerospace, and food related sectors, just to mention a few. That is because aluminum is a durable, corrosion resistant, and lightweight yet strong material, making it useful in many fields.

That being said here are tips to help when selecting industrial aluminum profiles.

One vital question to ask when selecting aluminum profiles is what do you need them for? What do you intend to use the profile for? Once you have an answer to that you can go ahead to find a suitable product for your needs. For example, aluminum profiles for some construction jobs may need to be hard for safety purposes. On the other hand, some food processing products may require aluminum profiles that are not as hard.

This has to do with the strength of aluminum profiles. They differ in strength and the grade you settle for again depends on the intended use of the profile. In some industries experts need strong profiles while others may need something more flexible. For instance, aluminum profiles to use in making chairs do not have to be as strong as those used to make products that carry more weight.

If you are worried about corrosion arising from various elements like environmental factors or chemicals, then you need aluminum profiles that can withstand these factors to ensure product durability and the safety of consumers. Aluminum profiles are used in making a vast range of items including solar panel frames, windows and piping. Ensure you choose those that suit what you are going to use them for.

If you are a manufacturer that does a lot of cutting and shaping to make different product parts, you want aluminum profiles that allow you to do your job easily and efficiently for enhanced productivity. Ensure you get exactly that from the manufacturer to avoid trouble and inconveniences.

Among their many uses, aluminum profiles are also used to make structures like television set equipment. Experts may use welding to join different parts and this where the weldability of a profile matters. You want an aluminum profile that is resistant to heat to allow you make what you need successfully.

Now that you understand that aluminum profiles differ in grades and characteristics, the following factors are also as crucial when purchasing aluminum profiles.

We have already mentioned this factor; the aluminum profile you settle for will depend on what you are going to use it for. Some projects may need hard, high strength profiles while others may require machinable and weldable profiles.

Remember to also check a manufacturer’s history and reputation. You should buy aluminum profiles from a company with a reputable name. It is even better when it has years of experience in the business so you are more confident that you are buying from a reliable source. That is not to discount companies that have been in business for less time. Such are worth considering as long as you do research on their products and customer satisfaction.

As a person in business, more interest is to cut costs but that should not be at the expense of quality. The aluminum profiles market has manufacturers that offer affordable products that are also high quality for safety and longevity. Take time to compare different companies and find one that fits your budget but also does not compromise on quality.

The best aluminum profiles manufacturer offers various products so customers get what they need. Customization should also be available so clients with particular specifications are also catered for. Furthermore, service delivery should also be top notch with responsive customer service.

Selecting industrial aluminum profiles is an easier process when you know what to choose. Depending on your needs, check the hardness, strength, corrosion resistance and weldability of the profiles to find what suits your business. Also spend money on quality profiles for the safety of your customers and the structural integrity of your products.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238