As someone or an entity that utilizes aluminum extrusions, you cannot afford to mess up your order. You need extrusions that match your needs to get the job done properly and ensure the structural integrity of whatever product you make.

For that reason, you need to be extra cautious when purchasing aluminum extrusions to ensure you get the best. Choosing the right extrusions starts with selecting the right manufacturer and below are tips on how to ensure you settle for the right aluminum extrusion manufacturer.

Quality is everything when it comes to aluminum extrusions. You want to buy these from a manufacturer that values high quality. High grade aluminum extrusions enable you to make secure products and structures that promote safety and durability.

Therefore, take your time when looking through different manufacturers to ensure you purchase only high-quality aluminum extrusions. The last thing you need is making products that do not last or put people’s lives at risk.

Remember to also check a manufacturer’s reputation when looking for aluminum extrusions. Go for a company with a good reputation, and such an entity has customers satisfied. A reputable aluminum extrusion manufacturer is reliable and has customer needs at heart. You can search online for reviews from other clients to get a more balanced look into a manufacturer’s reputation and customer satisfaction levels.

A reputable company also has industry certifications that enhance its credibility on the market.

You also want to buy aluminum extrusions from a manufacturer with well-equipped staff. Experience matters here. A workforce with the necessary skills and experience ensures customers get the extrusions they need for their projects. Yes, some manufacturers have been in business longer than others.

So, take time to look at the products a manufacturer offers, their quality, and also check customer satisfaction to help you decide which company to buy aluminum extrusions from.

Choosing the right aluminum extrusion manufacturer also requires you to find out a company’s area of specialization. Many manufacturers offer standard aluminum extrusions but some specialize in specific industries like the automotive or aerospace sector.

If you work in a particular field that utilizes aluminum extrusions, you should consider a manufacturer that specializes in that area. That way, you are certain of getting the different pieces your project needs.

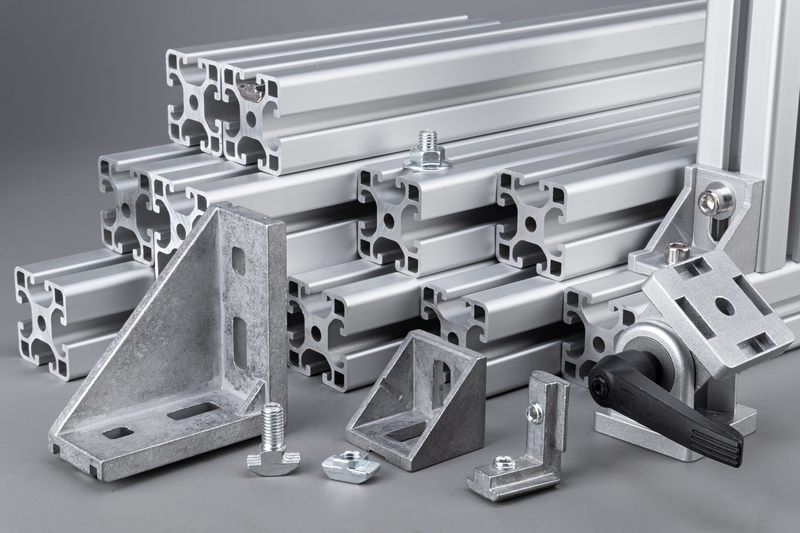

Now, aluminum extrusions are available in a variety of shapes and sizes. Getting standard extrusions, for example for construction, can be easy. However, if you are working on a project that requires parts with unique, customized designs, you want a manufacturer that can make them for you.

Therefore, as you search for the right aluminum extrusion manufacturer, check whether it also makes customized pieces. That way, you are certain of getting the exact item you need for your project.

An aluminum extrusion manufacturer that has experienced staff and provides quality extrusions also needs to have proper, up to date equipment. A professional aluminum extrusion company has the necessary tools to make extrusions that meet set industry standards.

You want to buy aluminum extrusions from a company that utilizes innovative, current technology to ensure customers get the best products in a timely turnaround period.

You cannot talk about purchasing a product without mentioning the price. Aluminum extrusion manufacturers can have differing prices for the product. That being said, you have to keep in mind extrusion quality too as you check different prices.

The bottom line here is finding reasonably priced aluminum extrusions that are also high quality. Compare costs from different manufacturers and find products that suit your budget and are also high quality for safety and longevity purposes.

Lastly you also need to check the customer support a manufacturer provides. You want to buy aluminum extrusions from an entity with responsive customer service. That means it is efficient so customers get the feedback they need in a timely fashion.

That aside, you should also check whether a manufacturer offers services like finish application and extrusion cutting. That way you are able to have your aluminum extrusions handled by one company instead of dealing with different entities.

Choosing the right aluminum extrusion manufacturer should be easier now that you are aware of the above tips. Don’t be in a hurry to make a purchase without conducting some research. Check a company’s reputation, extrusion quality, area of specialization, pricing and even customer support to be able to find the right fit for your aluminum extrusion needs.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238