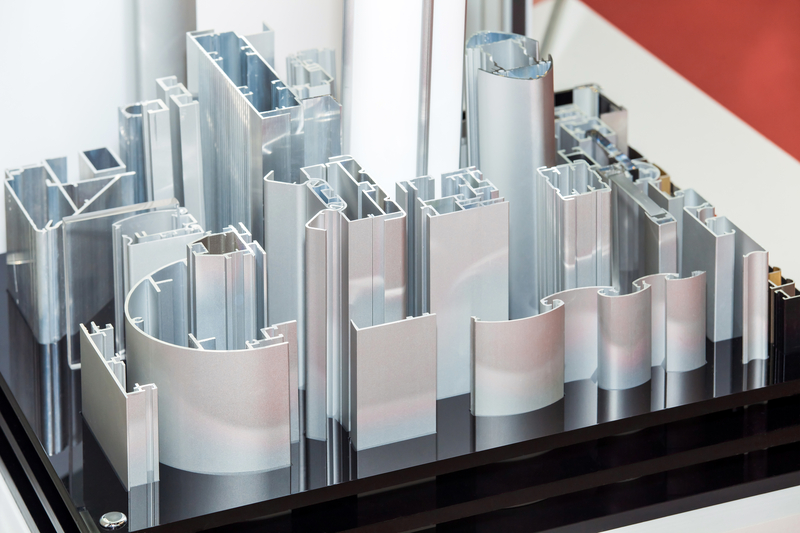

Aluminum is now getting all the attention it deserves. But it's leaving a bunch of questions, one being, where its extrusions best serve. So, how about we take a dive into the mystical world of aluminum extrusion. Starting off with demystifying what, in the industrial World, aluminum extrusion is all about. Picture it to be a wizard's spell that takes ordinary aluminum – light in weight, resistance to corrosion, high tensile strength, and top winner for conducting heat and electricity – and converts it magically into any shape you want it to have. It is like a dream tool at your hands to sculpt metal into your vision.

You will be surprised at how often you have come across aluminum extrusion without even knowing it, actually. Those sleek bleachers at sports stadiums or display cases in your favorite shops - this is the 'behind-the-scenes' unsung hero. It is that secret ingredient breathing life into everyday items like scaffolding, tables and carts.

Now let us move out onto the road to see how aluminum extrusion has redefined transportation. Be it panels, engine blocks, roof rails, transmission housings or chassis for automobiles, boats, trucks, subway cars or railways - aluminum extrusions are right there where strength-to-weight ratio matters the most.

Simply have a look at the cool Ford F-150, which dropped 700 pounds thanks to one thing: aluminum extrusion. And it is not only land vehicles; even RVs became a game changer in regards to recreational trucks and trailers simply because of this material. Its anti-rust quality along with its chrome-like aesthetics make it perfect for decorative purposes when used in transportation.

Ever wondered what goes on behind the closed doors of a bustling factory? Well, chances are, aluminum extrusion is at the heart of it all. Workbenches, carts, and inspection tables adore this stuff. It's lightweight yet incredibly sturdy, cost-effective, and a breeze to work with.

Moreover, its high degree of customizability makes it an indispensable tool in factory settings. Need to modify a workbench on the fly? No problem at all. Aluminum extrusion is the factory's trusty companion, ready to adapt to any situation.

Shifting our gaze to the realm of construction and architecture, aluminum extrusion shines as a true marvel. Its ability to withstand deformation caused by various factors makes it indispensable in mechanical applications such as ladders, building skeletons, and elevator shafts. These profiles excel at carrying heavy loads and absorbing shocks like seasoned professionals.

But that's not the end of the story. Aluminum extrusion also leaves its mark on architecture, from the grandeur of bleachers to the elegance of canopies and railings. It injects a touch of vintage charm into interior design, all while contributing to energy-efficient buildings by effectively managing heat.

Have you ever been captivated by the intricate frames of temporary exhibitions or the sleek lines of inventory cabinets and image frames? You're not alone, my friend. These visual delights owe their existence to extruded aluminum profiles. Not only do they look good, but they also offer remarkable functionality and ease of movement.

These profiles bring a touch of sophistication to display devices and beyond, demonstrating how aesthetics can seamlessly merge with functionality.

You'll find aluminum in busbars and various electrical equipment, thanks to its superior conductivity. Even lighting fixtures tap into aluminum's electrical prowess, though they may encounter thermal management challenges, especially with modern LED lights.

But here's a twist – fin-extruded aluminum emerges as a top-notch heat exchanger or radiator. It's easy to mount, lightweight, and can be painted to perfection when positioned above the ground. And speaking of electricity, aluminum extrusion plays a starring role in the support structures for photovoltaic (solar) panels, where minimal bulk, strength, and corrosion resistance are non-negotiable.

Have you ever wondered about the engineering behind aircraft? Well you can thank aluminum extrusion for its role in making planes soar through the skies. Its combination of strength, lightweight properties and resistance to corrosion makes it a favorite in aviation. Whether its aircraft frames or seats or even beverage carts onboard flights aluminum extrusion plays a role, in ensuring efficient travel experiences.

Exploring the ocean, we come across an application of aluminum extrusion, in the marine industry. Boat manufacturers highly appreciate its resistance to corrosion caused by saltwater. It is utilized in components, like boat hulls and masts guaranteeing that maritime vessels can endure the harshest circumstances. Additionally, it contributes to keeping the boats lightweight resulting in improved fuel efficiency and speed.

Art knows no bounds, and neither does aluminum extrusion. Artists and sculptors have discovered its potential to bring their creative visions to life. Its malleability and adaptability allow artists to experiment with shapes and forms that were previously unimaginable. The result? Art that blurs the line between creativity and engineering.

From, roads, architecture aviation to marine, green energy to emerging technologies, and even the art and sculpture, aluminum is expanding its territory through extrusions. It's an enabler of advancements, a catalyst for innovation, and a key player in shaping the world we live in.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238