For several decades now, aluminum frames have been a crucial part of the construction, medical and transportation industries and with good reason. Since their inception, these frames have advanced from being a standard option for simple frames to a more flexible product that can be employed in a wide range of applications.

This write-up will walk you through the benefits and applications of aluminum framing for various industries and also provide a few maintenance tips for these durable and long-lasting framing structures.

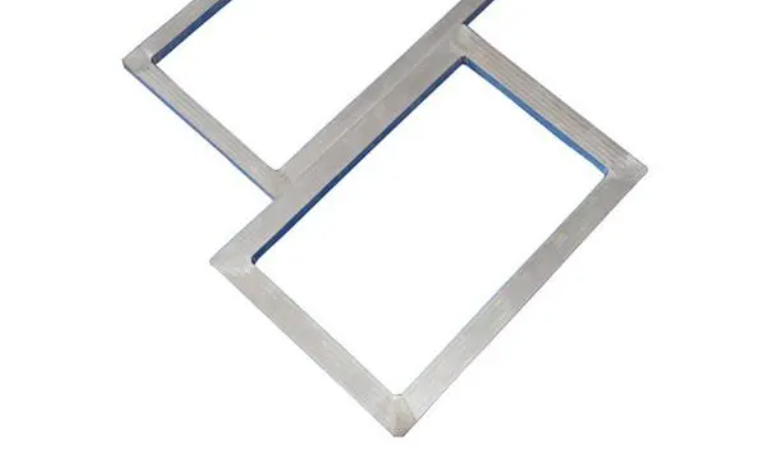

Aluminum framing is a modular setup fit together using extruded aluminum profiles. This framing system comprises accessories utilized to construct jigs, machine frames, and multiple other industrial products.

Most of these framing structures need the compilation of aluminum framing parts that have the same shape as the integrated aluminum profiles. For this reason, choosing an aluminum framing system calls for a shrewd analysis of product features and supplier reputation.

Now that you know what aluminum framing is, let’s delve into the broad scope of applications it is used for.

Considering it’s lightweight yet durable and long-lasting nature, aluminum framing can be used for numerous applications on different industries, including the following:

Aluminum framing is mostly used in the construction industry for both residential and commercial building construction. Some of the applications are:

A building has many components, with doors being among the most important. This is because it keeps intruders from accessing the property. Therefore, aluminum is one of the best materials to create such a component.

When aluminum framing is utilized as a door frame, it ensures durability. Moreover, it needs close to no maintenance, thanks to its corrosion-resistant nature. Again, aluminum features a better strength-to-weight ratio compared to steel, and it can be combined with other metals, including magnesium, silicon, copper and manganese, to make stronger alloys.

These alloys increase the tensile strength of aluminum, with some increasing it from 90 to 690 MPa. Something else to love about aluminum is that it becomes stronger when exposed to the cold. For this reason, it is a superior option than the metals that turn brittle under similar circumstances.

Besides functionality, door frames made from aluminum add an appealing look with their sleek nature, which makes it easier to find complementary designs. Overall, aluminum door framing is sturdy and provides you value for your money.

The other important structure of any building is the windows. They allow for ample ventilation, and natural lighting access to your property, leaving the interior feeling less cramped.

Aluminum framing is commonly used to make window frames, because unlike other materials, it will last a long time and survive even the harshest weather conditions.

Like door frames made from aluminum, aluminum window frames are affordable and durable, making them the perfect choice for industrial, commercial and residential buildings. Additionally, aluminum window framing can endure cracking and scratching brought about by heavy rains, strong winds, and high temperatures.

When it comes to appearance, you will love that aluminum framing is incredibly customizable. Plus, you can also get powder coated aluminum window frames finished with a color of your liking in tandem with extra corrosion resistance.

Railings are essential for any structure as they work as support that individuals hold on to avoid sliding or as barriers from vertical drops. Even though the primary reason for employing railing frames made using aluminum is due to their durability and safety, they are also aesthetically pleasing. Aluminum by itself is an easily customizable and pliable material.

Aluminum railings can also be powder coated with many colors or merged with glass pane for a more appealing appearance.

These ones help partition the bathroom and prevent water from leaking throughout the bathroom floor. Presently, homeowners have a wide range of options with regard to shower enclosure system materials. Nonetheless, using aluminum framing is the best option for several reasons.

To begin with, the durability presented by aluminum shower enclosure structures is perfect for keeping water within the shower cubicle, which reduces accidents and makes cleaning easier. On top of that, aluminum shower enclosure requires minimal maintenance than curtails, which accumulate moisture and soap residues.

These are the roofs’ framings. They dictate the shapes of a roof and ceiling and also offer structural support.

Provided that roof trusses need to be constructed using lightweight materials, which also have to handle pressure effectively, the aluminum framing is the perfect choice. Thanks to their robustness, these roof trusses can shield the structure from storms and strong winds.

Additionally, unlike wood trusses, which can be ruined by pesky termites, aluminum is corrosion and pest infestation resistant.

Here is yet another industry that uses aluminum framing. It shouldn’t come as a surprise that aluminum framing is used in the medical industry, considering its lightweight and corrosion-resistant nature.

Among the most common medical structures made using aluminum framing are hospital beds, gurneys, storage cabinets, workbenches, and many more!

Clearly, aluminum framing has a wide range of applications in the medical industry, from the doctor’s office to the patient's wards. This is thanks to how durable, flexible and highly customizable aluminum framing is.

Having covered all about the construction industry, let’s now see how aluminum framing is used in the transport industry before we talk about the medical industry.

Aluminum framing has numerous uses in this industry due to its lightweight nature. Besides, it is easy to work with and is solid enough to haul loads and endure high temperatures without buckling or sagging.

Also, aluminum framing also works to offer other materials support without requiring extra support from other members like steel or wood. Here are some common applications of aluminum framing in the transport industry:

Aluminum framing is used to make shipping containers because they are highly portable and lightweight. Additionally, it is easy to work with aluminum, so manufacturers can build multiple shipping containers within a short period.

Another use of aluminum framing in the transport industry is building bridges. For instance, the most popular bridge is the arch bridge. It is constructed using a broad scope of arches which are connected to each other using beams.

The arches are made using aluminum frames, which, as pointed out, are manufactured fast, facilitating swift and safe passage of heavy loads via narrow paths.

Generally, aluminum is used in constructing ships with spacious cargo holds and huge engines that can swiftly and efficiently move through water. Aluminum framing comes in handy in the construction process because it is lightweight, durable and sturdy enough to handle the harsh conditions surrounding the huge waterways.

Finally, aluminum framing is employed to make different automobiles, including trucks and small vehicles, which require durability and strength to carry heavy loads and drive through both smooth and rough roads.

Moreover, aluminum framing is used in making car parts like the chassis frame and wheels, which are vital car features, especially those that drive through harsh conditions like mud and pot-holed roads.

Having understood the applications of aluminum framing, it only makes sense that you know about the benefits of aluminum framing. While some of them are listed in the applications sector, like durability and longevity, most of them have not been mentioned.

Here are the benefits of aluminum framing:

Aluminum framing is more affordable than the alternative options on the market. As opposed to utilizing conventional welded steel for construction projects, you can use aluminum framing, which is a more affordable and stronger material.

Using aluminum framing allows the structure to be constructed quickly and affordably, which saves you both time and money. With multiple bolting connectors, and hundreds of profiles to choose from, structures for different applications and loads can be swiftly constructed without any special tools.

Affordable and eco-friendly, this is a reusable construction solution, making it cheap and simple to adjust the structure whenever necessary.

Additionally, this framing system helps boost productivity and employee comfort, because it is extremely versatile and can be easily applied to various workstations.

For more savings, selecting powder coated aluminum framing would be best, since it is good looking and saves you the time you would use to paint.

Aluminum framing can easily make complex structures, like buildings, bridges and industrial properties. On top of that, this framing structure supports the individuals who use it regularly.

For instance, aluminum framing is used in Manual production setups. In this instance it is easy to reconfigure the framing and it is sturdy enough to endure numerous changes, which increases productivity and employee comfort.

This is a process that boosts production procedures, which leads to customers getting exactly what they asked for. This produces a handful of advantages for the manufacturer, such as productivity boost, less inventory, faster rates at which new products reach the market, and so on.

However, lean manufacturing benefits the workers and employer as well. It can decrease the quantity of job-linked injuries and surge workers’ productivity. By using aluminum framing, you can easily implement lean manufacturing and make your business a success story.

Aluminum framing is incredibly versatile and can be used in different industries, and it also establishes safe structures. As pointed out, aluminum framing can be used in the medical industry, transport and construction industries thanks to its lightweight and durability. In addition, aluminum framing is corrosion-resistant, which adds to longevity.

Workstations are safer and more efficient when they are custom-built to meet the requirements of production. Aluminum framing will provide you with the necessary modularity needed for swift change.

Additionally, if you choose the powder coated aluminum framing, you won’t have to paint it. You will only have to connect them together, and once done, the powder coated aluminum framing will give it a sleek and appealing look.

With more than 100 aluminum profile designs and sizes to choose from, you can be able to turn your design ideas into a reality.

With all the different types and sizes of aluminum framing, they can be designed to meet your strength needs. Fortunately, with these framing systems, you don’t have to worry about excessive bending; each framing should come with a bend analysis, which helps you make the right choice.

Aluminum framing can be powder coated to meet your needs. This will also be time-saving because you won’t have to paint them once you are done with your construction project. This gives your project an aesthetically appealing look and a glossy finish.

Since aluminum is an elemental metal, its properties do not alter due to mechanical processes. This means it is highly reusable, and you can do this multiple times without impacting its properties. What’s more, it is non-toxic, which makes it one of the most suitable options if you are trying to reduce your business’s carbon footprint.

Aluminum has many benefits, including how impressively it holds thermal energy. At some point, aluminum framing was famous for its incredible thermal conductivity, or susceptibility to heat loss and gain.

Thermal boost technology in aluminum structures considerably decreases loss of heat when it’s cold, which results in a warm interior temperature on the aluminum frames, which is handy in moderating condensation, which in turn surges the building’s thermal performance.

Since aluminum is a lightweight metal, the assembly and installation of aluminum framing is usually less demanding compared to using other materials. For example, when installing aluminum stairs, you do not require a permit because the poles utilized to support the stairs are pushed into the ground with no concrete base.

Without having to pour concrete, these stairs can be used on a wide array of terrains. For example, they can also establish footing on rocky and boulder-filled terrain.

Customary steel structures need painting, priming, and welding to be ready for use. On the other hand, aluminum framing doesn’t need any of this. Additionally, no machining is necessary, and still aluminum is almost as robust as steel and cheaper. Lastly, assembling aluminum frame structures takes less time than with steel.

To guarantee the long-term robustness of aluminum framing, it is essential to take care of them. First, cleaning the frames regularly is vital to preventing corrosion and upholding their good looks. Moreover, any repairs required should be performed swiftly to avoid additional damage. You can also apply a protective coating to shield the frames from the weather elements.

It is also crucial to check the frames frequently for damage or wear. If you see any damage, you should take care of it immediately to avoid further weakening.

Again, if the aluminum framing is exposed to high temperatures or bad weather conditions, they need to be checked more often to make sure they are working properly.

We at JMA Aluminium have been in this industry since the early 1990s, which gives us close to three decades' worth of experience. For a long time, we have been working on the design, research, production & sales of aluminum alloy windows and doors, building profiles and industrial materials.

We take much pride in our 600,000+ tons of production capacity yearly. Our products are widely utilized in machinery production, construction, building templates, solar panels, and so many more industries.

Shishan Production Base

Nonferrous Metal Industrial Park, Xiaotang, Shishan Town, Nanhai District, Foshan City, Guangdong Province

Gaobian production base

Gaobian Zhangbian Industrial Zone, Dali Guangyun Road, Nanhai District, Foshan City, Guangdong Province

Company summary: + 86-757-85558828

Fax: + 86-757-85550238